The electrical system that our 2018 Airstream Sport 22′ camping trailer came from the factory with was pretty basic. It had a single open cell lead-acid battery capable of powering the lights, the furnace blower, water pump, stereo, and a few USB outlets. However, it didn’t come with an inverter, needed to run any AC appliances (microwave, toaster, blender, etc) while off grid. It also came with only a very basic voltage-based battery monitor that doesn’t give much information about how much battery capacity is being used or is remaining. In this post, I’ll describe the first set of electrical system upgrades we’ve installed in the trailer.

Requirements

As configured from the factory, the Airstream would be great for weekend getaways or longer stints at campgrounds with electrical hookups. However, we’re hoping that on our longer travels we’ll be able to spend a lot of our time boon-docking at either smaller campgrounds with electrical hookups or off the grid entirely on BLM or National Forest land.

The truth is we don’t need a lot of electricity to be comfortable. The LED lights take very little power and the water pump will run infrequently. In colder weather, the furnace fan could, however, likely draw down the factory battery in a day. There are also some ‘luxuries’ that we’d like to have, since this will be our home for an extended period of time:

A blender (300-900 watts): In warmer weather, smoothies would be a nice indulgence.

A toaster (~1000 watts): Making toast over a propane stove is possible, but I know I’d burn it half the time and set off the smoke alarm.

The dehumidifier (300-600 watts): In cool weather, the dehumidifier has been great to help us dry out our wet clothes and keep the trailer from getting too damp.

Charging a MacBook Air (~60 watts): So that we can keep blogging! Not a very high-power item though.

The microwave (1500 watts): Again, totally not a necessity, but when we’re traveling it’s nice to be able to just toss left-overs in the microwave rather than dirtying a pan and using our limited water supply to wash it.

The convection oven (1000 watts): Our trailer didn’t come with a propane oven, which at-first we were very disappointed about (Sarah loves to bake) — however, since buying the trailer I’ve read that most people that have them hate their propane camper ovens as the temperature varies too much for consistent baking. The convection oven uses a lot of electricity, but it’s much more consistent (and can be used in combination with microwaves for quicker baking of certain dishes).

Fantastic fan (36 watts): The roof vent fan is pretty efficient, but in hot weather we may want to run the fan all day (since we won’t be able to run the air conditioner when we don’t have hookups).

System Overview

With these things in mind, and with the space constraints of our smaller trailer, I designed an electrical system upgrade which I’ll install in 3 phases:

Phase I: Protection, monitoring, lithium batteries in the Airstream and charging

This phase will get us everything we need to run the appliances above, albeit with limited usage. Charging will occur primarily when towing. We’ll be able to bake something in the convection oven for an hour or two, for example, so long as we won’t be using too much more electricity before the next time we tow. This phase will include:

- 200 amp-hours (~2700 watt hours) of capacity from two Lithium Iron Phosphate batteries

- A 2000 watt inverter

- A current-based battery monitor system

- A surge protector (for when we do have hookups)

- An upgraded AC-to-DC charger specific to lithium batteries

- A DC-to-DC charger to allow the lithium batteries to be charged by the van while towing

- An upgraded electrical connection between the van and trailer to be able to deliver higher current

Phase II: Lithium batteries and charging in the van

This phase will upgrade the battery capacity of the van. We’ll be able to park the van in the sun, even when the Airstream is parked in the shade, to allow the existing 200 watts of solar panels on the roof to charge up the cells. Since there’s more room on the roof still, we’ll add another 100 watts for a total of 300 watts of solar. When we’re out running errands or adventuring for the day, the van’s alternator will charge them up. And when we need to charge the Airstream batteries up, we’ll just move the van up close to it and plug them together.

Phase III: Solar panels on the Airstream

In the final phase, we’ll add 350 watts of solar panels to the Airstream and an additional 100 watts of solar to the van so that we can charge both battery banks faster.

Phase I Component Details

Surge Protector

Without a surge protector, it’s possible that a power surge or low voltage at a campground could damage components in your RV such as your air conditioner, microwave, etc. Low voltage is a common problem, especially at older RV parks that have inadequate wiring. Buying a surge protector is a relatively inexpensive way to protect your investment.

For RV surge protection there are 2 possible routes to take:

- Buy a portable surge protector, which plugs between the RV park electricity source and your 30A/50A wiring harness.

- Install a hardwired surge protector inside your RV.

Portable surge protectors are somewhat cheaper than hard-wired, and you avoid the hassle of having to install the hard-wired device. However, the trade-off is that you need to remember to hook it up each time you plug your rig into electricity (and you run the risk of having your ~$100 device stolen as it plugs in outside the RV).

For both hard-wired and portable surge protectors, there are two main brands to choose from: Surge Guard and Progressive Industries. I read plenty of good reviews about both brands, so I just went with the one that was cheaper. For me, that was the Surge Guard 30 Amp Hard Wired unit (there’s an equivalent 50 Amp unit if your RV has a 50A electrical system). I also purchased the Surge Guard 40300 Remote Display, which enables you to see exactly what the problem with the power is when the Surge Guard goes into protection mode, and also enables you to see the amps that you are currently drawing when the power is working.

Lithium Batteries

In an RV, there are 3 typical types of batteries used:

Open Cell Lead-Acid Batteries are the cheapest, and our Airstream came with a single open cell battery with approx. 40 amp-hour of usable capacity. The advantage of these batteries is that they are cheap, and the disadvantages are everything else:

- During charging open-cell lead acid batteries release hydrogen gas, so they must be either installed outside the RV or in a sealed compartment vented to the outside.

- Lead acid batteries have relatively high self-discharge, so they need to be kept hooked up to a charger when stored for long periods.

- Open-cell lead acid batteries need to have distilled water added to them frequently.

- Their weight to capacity ratio is high– i.e, they are heavy

- The more they are discharged, the shorter their useful lifespan. Therefore, the usual recommendation is to not discharge them more than 50%.

Closed Cell Lead-Acid Batteries are an upgrade from open-cell. The advantage over open-cell is that they don’t releases gases when charged and they don’t need water added, as they are completely sealed. The other disadvantages, however, remain. They are also the most expensive type of battery per charge cycle. For example, a 200ah gel battery (one type of closed-cell lead-acid battery) might cost you about $400, weighs 128 lbs., gives you 100ah of usable capacity, and might last for 1100 cycles. That’s $0.36 per 100-amp-hours used over the lifetime of the battery.

Lithium Iron Phosphate Batteries (LiFePO 4) are the most expensive up-front option, but they also last for many more cycles and have many other advantages over lead-acid:

- Like closed-cell lead acid, they don’t vent gasses, so they can be installed inside

- They can last 3000-5000 charge cycles (and even after that many, they should keep working with some diminished capacity)

- They can be charged quicker and more efficiently. This is especially important in solar systems when each watt is precious– lead acid batteries, especially in the last 20% of their charge cycle, waste much of this energy as heat.

- They can be discharged more quickly. This is important when powering watt-hungry appliances like a microwave.

- They can be discharged to their rated capacity without damaging the battery.

- They can weigh about 1/4 the weight of similar capacity lead-acid batteries (after taking into account that the actual capacity of a lead acid is 50% of the rated capacity)

Traditionally, lithium systems required some additional external electronic components that lead acid batteries don’t need. For example, a low voltage cut-off circuit to prevent the batteries from getting drained past their rated capacity. They also require a low-temperature charging cut-off, as charging a LiFePO4 battery when the temperature is below freezing can also damage them. Lately, however, manufacturers have started making LiFePO4 batteries conveniently sized to match traditional lead-acid batteries, and with all these extra electronics built-in. In theory, this means you can drop a lithium battery in where a lead-acid battery formerly was and be done with it. In practice, however, you’ll likely want to make additional changes. For example, upgrading your charger in order to take advantage of the faster charge time of lithiums.

We chose to go with a pair of Battle Born 100ah LiFePO 4 batteries. These bad-boys are $950, but retain ~80% of their capacity after 3000-5000 charge cycles, and weigh only 29 lbs. If we assume the battery will last 4000 cycles, that’s $0.24 per 100 amp-hours used over the lifetime of the battery (33% cheaper than the Gel battery while being almost 100 lbs. lighter, among the other advantages).

Battery Monitor

I’ve researched RV battery monitors on several occasions, and in my mind there’s only one monitor worth getting: the Victron BMV-712 Monitor with built in Bluetooth. The monitor has a small, unobtrusive display that can be installed just about anywhere … and it also has bluetooth connectivity, so you can see everything that you can see on the built-in display on your phone (and more), which alleviates the need to even mount the unit in a visible location.

Most RVs, including ours, come with a basic voltage monitor. These are better than nothing, but they don’t tell you enough information to really understand the state of the battery charge or your power consumption. First of all, the voltage of a battery depends on the current load on the battery. On a typical lead-acid battery, voltages below about 12v mean that your battery is low and should be charged. However, if you’re currently drawing a heavy load off the battery, the voltage could report as below 12v even if the battery is fully charged– turn off the load and the voltage will jump back up. A battery voltage monitor also tells you nothing about the rate at which you are depleting the battery … e.g, will I make it through the night running my furnace fan?

In contrast, a battery monitor like the Victron BMV-712 measures the voltage drop across a shunt resistor placed between the battery and the load. The more current going in or out of the battery, the greater the voltage drop across the shunt. This allows the monitor to measure the current going in or out of the battery. By configuring the monitor with the capacity of your battery (e.g 100 amp-hours), the monitor can approximate the amount of capacity remaining in the battery. For example, with a 100 amp-hour battery if the monitor observed 10 amps being drawn from the battery for 1 hour, then 90 amp-hours would be remaining.

The monitor can also tell you time-until-empty. For example, with a fully charged 100 amp-hour battery and a current flow of 10 amps, there are 10 hours of charge remaining at the current rate of depletion.

Inverter

Inverters are used to turn DC (direct current) into AC (alternating current). This allows you to power household appliances that require 110v AC from a 12V DC battery. Inverters come in two flavors– pure sine wave and modified sine wave. Modified sine wave inverters are cheaper, and are fine for certain electronics (such as computer chargers, phone chargers, etc). However, AC motors cannot be run off of a modified sine wave inverter (such as a blender).

Inverters are rated by their max wattage that they can output continuously, as well as a surge wattage that they can output momentarily (such as when a motor is starting up). The highest wattage appliance we want to power is our microwave at 1500 watts, so we went with a 2000 watt inverter (I felt more comfortable having a little extra headroom). I also wanted an inverter cable of having a remote power switch so that it could be installed hidden away and then remotely turned on and off.

There are lots and lots of very cheap inverters on the internet, but many of them have lots of scary sounding reviews of them spontaneously catching fire. Although slightly more expensive, I went with the Xantrex PROWatt 2000 as Xantrex is a trusted brand in the industry. I also bought the Remote Power Switch.

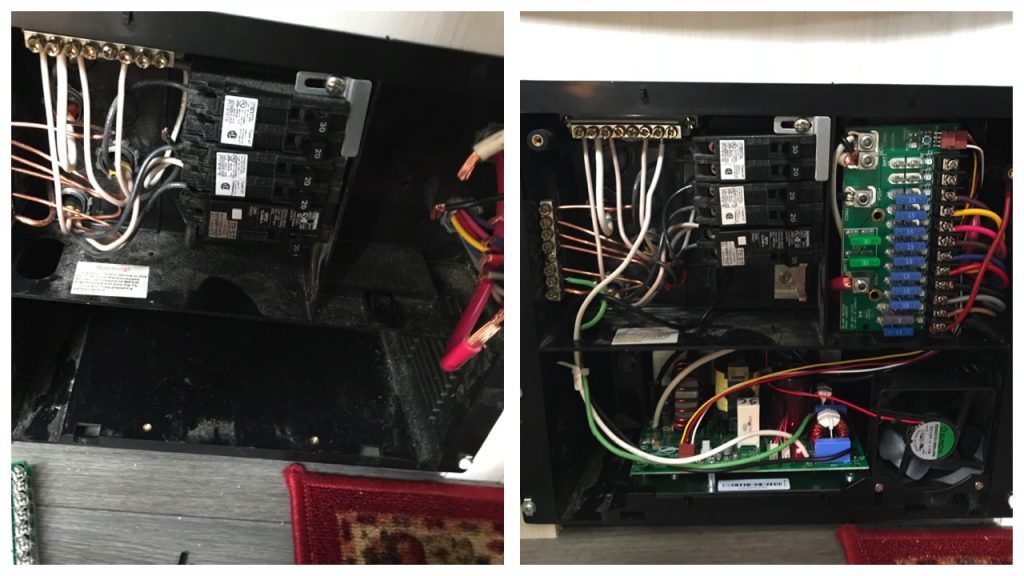

AC-to-DC Charger upgrade

Our Airstream came with the WFCO brand WF8955 55-amp battery charger. This charger has a ‘bulk’ charge voltage of 14.4v, an ‘absorption’ voltage of 13.6v and a ‘float’ voltage off 13.2v. Three-phase chargers like this are designed for lead-acid batteries, as these batteries can charge quickly (‘bulk’) for the first ~80% of their capacity, and then need to be slow changed (‘absorption’) for the remaining 20%, followed by a ‘float’ to keep them topped off. Technically, this charger meets the requirements outlined by Battle Born for their batteries. However, in practice I’ve observed that it spends most of its time in absorption mode, even if I drain the lithium batteries a bit. At 13.6v the lithium batteries won’t fully charge and the charge won’t equalize between lithium battery cells. For this reason, I’m upgrading to a lithium specific charger.

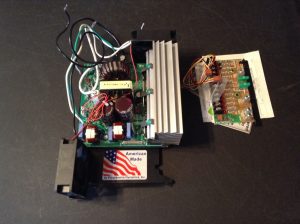

Progressive Dynamics offers a line of drop-in replacements for factory RV chargers. If you look up the model of your existing charger, then you can use this table to determine the correct replacement. Unless you plan on re-doing the wiring between the charger and the battery, you should use a replacement charger of the same or lower wattage so as not to over-load the wires.

For our Airstream, the PD4655LIV 55 amp charger was the correct replacement unit.

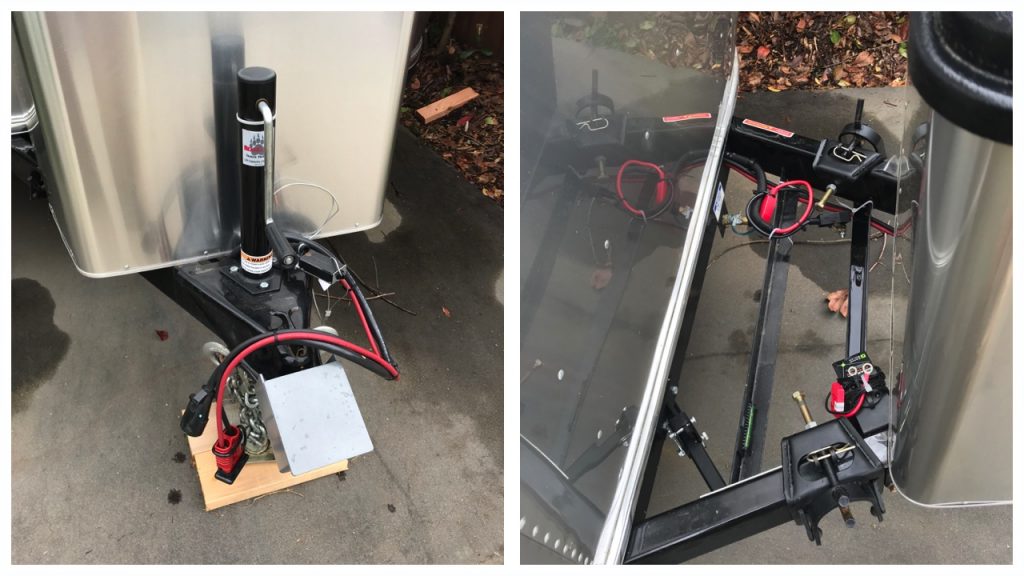

DC-to-DC Charger and towing harness

Any trailer that has its own electric brakes requires a 7-way towing connector (as opposed to a 4-way which you can use on smaller trailers that only have brake lights and turn signals). The 7-way connector is capable of charging the trailer from the tow vehicle’s inverter. However, the connector uses thin 12-gauge wires, which are not capable of transferring large amounts of power.

Further, the tow vehicle’s inverter likely outputs somewhere between 13.8 and 14.2 volts (and the voltage at the trailer will be lower due to the voltage drop over the wire). This is not a high enough voltage to fully charge the lithium batteries.

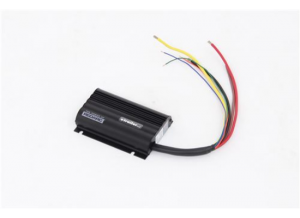

To enable the lithium batteries to be quickly fully charged from the van, we’re installing the Redarc BCDC1240D DC/DC charger. This is the only product of its kind I was able to find in my research. This device will reduce or boost the voltage coming from the van’s alternator to the 14.4v needed to correctly charge the lithium batteries, and will produce up to 40 amps. Further, it accepts input from solar panels and will use energy from the panels prior to taxing the alternator (I’ll hook up this solar capability in Phase III).

Since the 12 gauge 7-way connector wires aren’t adequate to transfer 40 amps, we’re going to install a winch connector using 4 gauge wire between the van and trailer.

Phase I Parts List and Cost

| TOTAL | $3553.83 |

| Component | Cost |

| Two BattleBorn 100ah LiFePO4 Batteries | $1900.00 |

| Redarc DC to DC Charger, 40 amp | $429.72 |

| Progressive Dynamics PD4655LIV Lithium Battery Charger | $249.00 |

| 4 AWG Wire (15ft) + Heat Shrink + Lugs | $43.68 |

| 4 AWG Wire (Extra 10ft) | $28.17 |

| 1/0 AWG Wire (10ft) + Heat Shrink + Lugs | $61.36 |

| 10pcs 1/0 Gauge Battery Lugs | $12.03 |

| Winch Connector | $16.99 |

| Single Stud Junction Block (Used to connect trailer charging harness cable to Redarc charger) | $10.99 |

| 4-Post Power Distribution Block (Red) | $22.00 |

| 4-Post Power Distribution Block (Black) | $22.00 |

| Xantrex PROWatt 2000 Inverter | $400.16 |

| Xantrex PROwatt Remote Switch | $21.00 |

| 80-amp Circuit Breaker (Installed in van for trailer charging harness) | $21.99 |

| Battery Disconnect Switch | $24.44 |

| InstallGear 250AMP ANL Fuse (bought as 2-pack, one to be used in Phase II) | $6.99 |

| 30 Amp Automatic Transfer Relay | $76.76 |

| Victron BMV-712 Battery Monitor | $206.55 |

Installation

The diagram below shows an overview of how the components were connected together. I used large gauge 1/0 wire to connect the components together (to be able to handle the 150+ amps used by the inverter), except for the long run between the van and airstream, which I used slightly thinner gauge 4 wire (as it only needed to handle 40 amps).

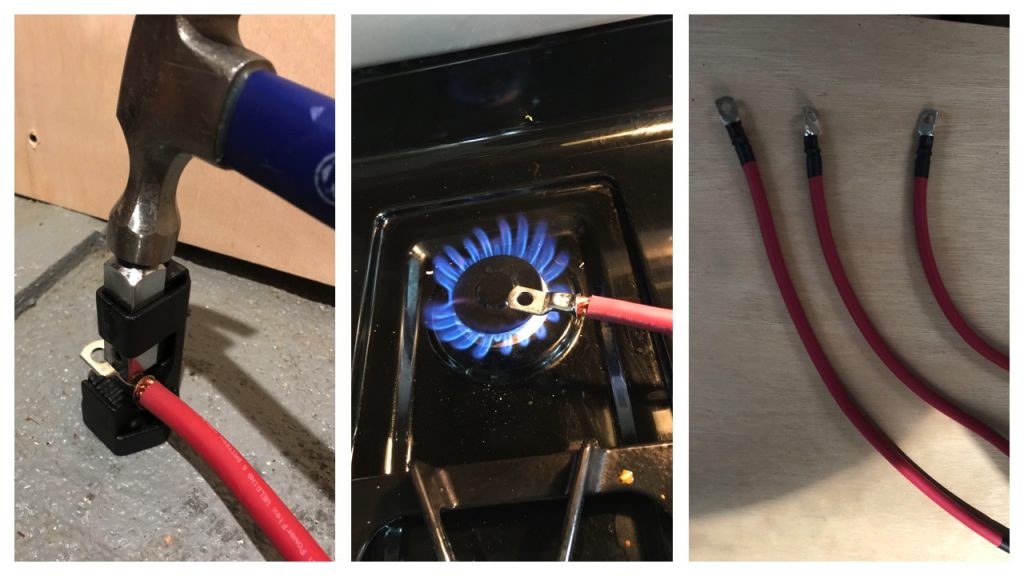

One of the biggest challenges was just making the cables with the large wires. First I used a lug crimping tool and a hammer to crimp the lug connectors to the ends of the wires. Then I soldered. I didn’t have a blowtorch, and my soldering iron wasn’t hot enough for such big wires, so I ended up soldering the lugs onto the wire on our gas stove.

Installation involved 5 areas of the Airstream:

The front-left corner under the bed: In our particular airstream, there’s a spot under the bed that contains the hot water heater and some electrical wires. There is a lot of unused space in this compartment, so this is where I chose to install all of the DC components of the system (batteries, inverter, dc-to-dc charger).

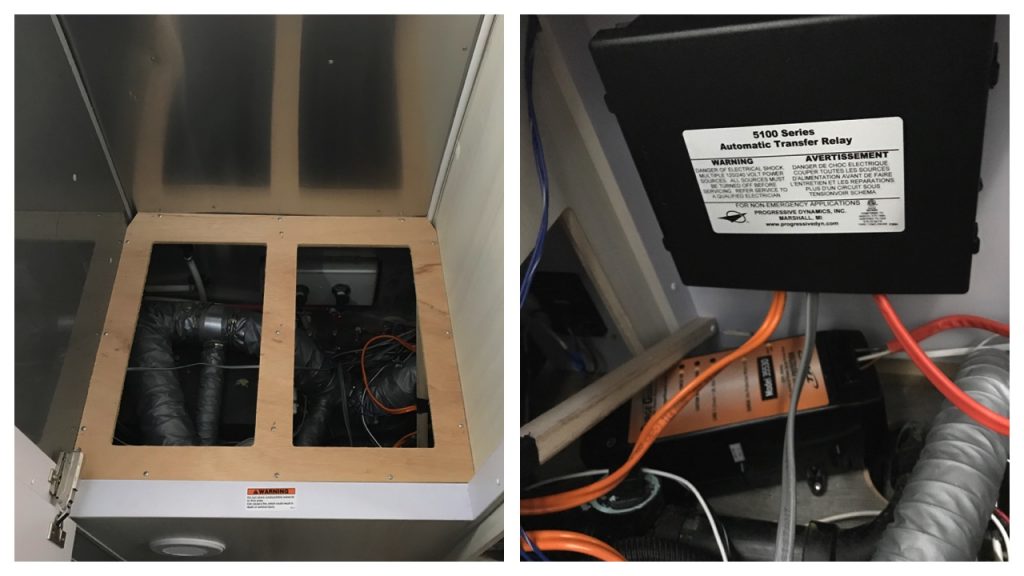

Under the closet: In the rear of our camper is the main closet. If the floor is removed from the closet, a service area is revealed that contains the water pump, heating ducts, and wires. It’s also right next to the fuse box and where the AC service line from the exterior hookups come into the trailer. This is where I installed the AC components (surge protector, automatic transfer switch, and upgraded ac-to-dc charger).

In the bathroom: The existing tank and battery voltage monitor panel is on the wall in the bathroom. This is a convenient place to install monitors since the wall is hollow so wires can be hidden. I installed the battery monitor and remote switch for the inverter here. I also installed the remote monitor for the surge protector on the opposite side of this wall (inside the closet) — mostly just because this particular monitor is a bit large and ugly, and rarely needs to be accessed.

On the front a-frame: This is where the existing deep-cycle lead acid battery had been installed from the factory. I removed this battery and the battery box. I then ran the gauge 4 wires through the same hole in the floor that the existing battery cables ran through and added the winch connector.

Trying it out

With the install done, I tested out a few things.

- The microwave works from the batteries (both in microwave and convection mode)!

- I plugged the van into the Airstream, using the winch connector, and observed that the lithium batteries were charging.

- I turned the TV on and the inverter on while the camper was plugged into an external power hookup. Then I unplugged the external hookup. I was hoping that the automatic transfer switch would be fast enough that the TV would seamlessly switch from external AC power to the inverter, acting as a sort of battery backup … but it didn’t. Power flickered for a second and the TV turned off and then back on.

- Just for the heck of it, I tried running the air conditioner off of the inverter. It didn’t work (I didn’t expect it to).

- Although I installed the automatic transfer switch, the AC-to-DC charger is still hooked up to the AC power panel. This means that when running the inverter, the inverter is powering the charger. It creates a weird loop where the battery is essentially trying to charge itself, and in the process losing energy due to the inefficiencies in the system. Long story short, I need to manually turn off the breaker for the charger each time I want to use the inverter, at-least until I devise something better.

Hey Justin, I have a 1947 Curtis Wright and I am getting ready to redo the electrical. I found this post and it’s similar to what I have in mind. Essentially, I’m wanting to do this:

1. 200ah of Battleborn batteries

2. Xantrex inverter

3. Xantrex transfer switch

4. Progressive Dynamics PD4655LIV charger

So, a simplified version of what you have… And I was wondering if you have any thoughts after using this stuff a while. Anything you’d do differently?

Thanks a ton,

Ryan

Hi Ryan–

The system has been working really well for us, and I think the set of gear you listed would work great for you. The 200ah of Battle Born batteries feels like a ton of power for us, so long as we’re not using the microwave / convection oven a lot (yesterday on Thanksgiving we used a bit over 200 amp hours cooking). The Xantrex inverter has had no problem running the 1500 watt convection oven for over an hour. The inverter does have a fan that’s a bit noisy that comes on when it’s working hard, so consider that when deciding where to install it (and also make sure it has good airflow of-course). Keep the wire run between the batteries and the Xantrex inverter as short as possible using large gauge wires.

The PD4655LIV has worked flawlessly as well. You don’t have it on your list of gear, so not an issue for you, but the Redarc DC-to-DC charger’s lithium charging voltage is a little less than what the Battleborn batteries want, so it doesn’t *quite* fully charge the batteries (although it probably gets them to 99%) … when we plug into shore power the PD4655LIV tops them right off.

The one thing I would do differently– although again, it sounds like it won’t apply to your project– is that I wouldn’t use the thin pre-run solar wires that came in our Airstream. Even though we have 350 watts of solar panels on the roof, I never see more than about 180 watts of power generated from them (where as our van has 300 watts of panels and I sometimes see 250 watts of power generated). I attribute the difference to the fact that the wires from the panels on the Airstream to the solar charge control are probably 40-50 feet and probably 12 gauge wire (where on the van they are 10 gauge and maybe 10 feet). However, I’m still nervous to cut new holes on the outside of our camper, so for now I’m leaving it 🙂

Good luck on your project!

Hi Justin. I have a 1978 ambassador I’m figuring out this exact solution for. Can you tell me if you ever solved the charger / inverter loop problem? If so, how?

Thank you

Hi Martin. I haven’t solved this problem yet. Sometimes we still turn the inverter on and forget to switch off the breaker for the charger… I don’t realize we’re draining the battery until I try to turn on a high-power appliance and the inverter overloads and shuts down. It would be relatively easy to wire the charger directly to the shore power before the transfer switch relay … however, the reason I haven’t done this is because I would need to add a breaker between the shore power input and the charger, and I can’t seem to find a 110v “stand-alone” breaker that doesn’t need to be installed in a large breaker panel .. and I also haven’t found any reasonably sized small breaker panels (aside from $200 Marine panels from BlueSea systems) .. My only thought at this point is that I could modify the breaker panel that’s already in the Airstream by cutting the “hot” bus-bar in the breaker panel into two sections … and then wire the separated section of the bus bar directly to the shore power.. but I don’t love this solution :). If you find a solution I’d love to hear it!

In my research I think a 120vac 30a contactor (big relay). Shore power would be wired in normally closed on one side (after convertor) and inverter on other side. At the push of the inverter remote button it would open the convertor circuit and close the inverter side thus deleting the convertor out of the loop. So one button. No new runs or other breakers and pretty automatic. https://www.amazon.com/dp/B01DYY777M/ref=cm_sw_r_cp_api_i_ymFtDbFVQK001

Haven’t tried it but I think it should work. If any actually certified folks care to grade my homework, please do before I let the smoke out of something.

Ahh yes– that relay you found is very similar to the transfer switch that I have installed. You inspired me to go ahead and fix the problem: https://www.wackywanderers.com/2019/08/10/fixing-the-inverter-charger-power-loop-in-our-airstream/

Thanks for all the detail, Justin – I just bought the same unit and we’re looking at similar upgrades. I did much of this on our previous trailer, a little A-frame popup, using

100 ah gel battery (not enough)

Simple switch to shut off built-in converter when running on inverter power (often forgot to flip it)

Direct charging through TV alternator using 10 g wire (anemic)

30 amp receptacle installed in battery box and connected to inverter (power cable for trailer was close enough to battery box to make this practical, even while driving – won’t work on the Airstream)

Your solutions have addressed most of what was inadequate with that setup, but I have a couple of questions:

1. If I’m trying to minimize propane usage, does it make sense to run my 3-way fridge on 110 or 12v rather than propane when off grid? Do you know what it draws?

2. Would it be worthwhile to install a completely independent small 12v solar array just for the fantastic van (assuming it’s most needed when the sun is shining)? Or is it smarter just to keep it linked into the overall system?

3. I’m assuming the a/c wouldn’t work because the startup load was too high. I have read somewhere that there are capacitors that even out motor/compressor startup loads – worthwhile?

4. Wouldn’t a Lil Buddy propane heater be worthwhile for cold weather (with a window cracked, of course)? No fan, quieter, and the radiant heat warms up the interior more efficiently).

5. Since you had to install a separate winch connector to handle the load on the Dc/DC Charger, I wonder whether an alternative might be to run 110v power to the trailer from an inverter installed near the TV battery. Run an ordinary extension cord across the trailer hitch and connect to main trailer power inlet line. no current drop problems, and no snaking big 2 or 3 gage wires through the tow vehicle. Just need to make sure a relay cuts off power to this line when plugged into shore power so you don’t have a hot plug hanging off the trailer.

Thoughts?

Wow Gary– it sounds like you did indeed have a very similar setup on your last trailer– nice work! Here are my thoughts to your questions:

1) The 3 way fridge is very inefficient to run on 12v or 120v since it’s just an electric heating element. I measured the draw at one point– I remember something like a continuous 10amps. If I were wanting to minimize propane use, I would switch the fridge to a 12v compressor fridge (as long as you don’t mind the noise). I did a lot of research at one point and found a fridge, the Dometic Coolmatic 140S, that has about the same dimensions as the factory 3-way fridge.

2) If you’re already installing solar for the whole unit, then I would keep the fan connected to the main system. The fan really doesn’t draw much anyways (maybe 1amp).

3) I also researched the capacitors.. yes, if you want to run the A/C on battery, it’s an option. However, with the amount of power the A/C draws, you would need a lot more batteries to make it practical. With the 200 amp hours of lithium batteries I have I could maybe run the A/C for an hour if I had a soft start capacitor …. doesn’t seem worth it. We found that just having a few small 12v or even USB 5v fans was enough for our winter travel …. but I’m sure it would be a different story if we were boon docking in hotter areas.

4) We used to have a Lil Buddy heater in our first camper van. The main issue with them is that they create a lot of moisture, which is usually the last thing you want in your trailer when you’re cold weather camping.

5) Yes– I think running 110v power for charging from the TV is a great idea. I actually met someone on the road that had done exactly that, and I thought “if I could do it again, I’d do it that way”. There is definitely voltage drop over my charge lines, and I usually don’t get more than 20a charging current despite the charge controller being rated for 40a.

Good luck on your project!

Hello Justin … we have the exact same trailer you do and I am ready to upgrade. In cold weather we are lucky to make the night with the furnace on. We never use ac power when boondocking and rarely miss it.

Phase 1:

-Battle Born 100aH

-Victron 12/12-18 (I plan on using 7way and this is my choke)

-Victron 100/20

-Victron BVM-712

Phase 2:

-Battle Born 100aH

-Progressive Dynamics 4655LI

Phase 3:

-2 additional Vamp 90Ls

My question: Do you have heat issues where you installed the batteries/controllers? Is a fan needed?

Thanks….

Rob

Hi Rob— we have not had any heat related problems with the system… however, we also have not camped in any extremely warm weather, as the bulk of our travel has been in the winter. I sleep with my head on top of where the batteries and charge controller are located and I’ve never noticed any extra heat rising up. Sorry to not have better data! Best of luck on your project!

Hi Justin, thank you for your post! I’ve been looking for instructions about how to install an inverter but it’s really hard to find one like this! I’m going to install a Victron inverter/charger to our Bambi of the same layout as your Sport, but I have some questions about wiring through the unit. 1) How did you wire from the shore power outlet through the kitchen to the bed? Did you need to remove the kitchen cabinet? 2) When you ran the wire from the old battery box through the hole to the bed, did you need to replace the black cable tube as well? Thanks!

Hi Joe. On our Bambi there is a an angled piece of thin sheet aluminum at the base of the wall between the kitchen cabinet and bed. After removing that and opening the trap door at the bottom of the main closet, I was able to feed Romex cable all the way behind the kitchen cabinets without taking them apart (it took a few tries to not have the wire get caught on anything). I left the wires that went to the old battery box in place— I just coiled them up and zip tied them to the A-frame and then disconnected them from the junction box under the bed.

I used the same path for the electrical upgrade to my Bambi. If you remove the microwave you get access to the space Justin speaks of. It greatly helped me run wires without removing allot of stuff.

Hi Justin, thank you for the info! I just tried it yesterday. There’s about 1 inch of the aluminum cover under that cabinet, so even after removing that two screws, I was not able to remove it. Did you easily slide it out after removing the screws, or pull it hard? Thanks!

Hi Joe— were you able to get the aluminum cover off? Mine was definitely not under the cabinet..